The Transformative Role of a **Rapid Prototype Manufacturer** in Modern Business

In today’s highly competitive landscape, businesses are constantly seeking ways to innovate and adapt. One critical aspect that plays a pivotal role in this journey is the collaboration with a rapid prototype manufacturer. This article delves into the world of rapid prototyping and explores how it helps businesses streamline their development processes, reduce costs, and enhance product quality.

Understanding Rapid Prototyping

Rapid prototyping is a dynamic process that enables companies to create a physical model of a product in a fraction of the time required by traditional manufacturing methods. This approach not only accelerates the design and testing phases but also significantly reduces the risks associated with product development.

The Core Benefits of Rapid Prototyping

The advantages of utilizing a rapid prototype manufacturer are multi-faceted. Here are some of the primary benefits:

- Speed: Rapid prototyping minimizes the time taken from concept to physical model, allowing businesses to speed up their time to market.

- Cost Efficiency: By identifying design flaws early in the process, companies can save on expensive modifications during the later stages of production.

- Enhanced Collaboration: Prototypes serve as tangible representations of ideas, facilitating better communication among teams and stakeholders.

- Iterative Testing: Early models allow for thorough testing and improvements based on real-world feedback, ensuring higher product quality.

- Flexibility: Rapid prototyping supports a wide range of materials and designs, accommodating the unique needs of various industries.

The Process of Rapid Prototyping

Understanding how a rapid prototype manufacturer operates is essential for leveraging its full potential. The process typically involves several key stages:

1. Design Development

Initially, the concept is transformed into a 3D digital model using advanced computer-aided design (CAD) software. This step is crucial as it lays the foundation for the prototype.

2. Selection of Prototyping Method

Depending on the requirements, manufacturers may choose from various prototyping methods, including:

- Stereolithography (SLA): Utilizes UV light to cure liquid resin into hardened plastic.

- Selective Laser Sintering (SLS): Employs laser technology to fuse powdered materials.

- Fused Deposition Modeling (FDM): Extrudes thermoplastic filament in layers to create the prototype.

3. Prototype Fabrication

Once the method is selected, the actual fabrication of the prototype begins. Precision is of utmost importance during this phase to ensure accuracy in the final product.

4. Testing and Iteration

After fabrication, the prototype undergoes comprehensive testing. Feedback is gathered to identify any necessary changes, leading to further iterations until the desired specifications are met.

Why Partner with a Professional Rapid Prototype Manufacturer

Choosing the right rapid prototype manufacturer is paramount for businesses wanting to achieve successful outcomes. Here are several reasons why partnering with professionals like Deep Mould can make a significant difference:

Expertise in Metal Fabrication

As a leading player in the metal fabrication industry, Deep Mould brings extensive experience in both rapid prototyping and traditional manufacturing practices. This dual expertise ensures that you receive products that not only meet design specifications but also conform to high operational standards.

State-of-the-Art Technology

Professional manufacturers are typically equipped with the latest technology and equipment. This investment in modern tools allows them to produce high-quality prototypes with exceptional precision.

Customized Solutions

Every project is unique; thus, a good rapid prototype manufacturer will offer tailored solutions that align with your specific business goals and project requirements, ensuring a perfect fit for your operational needs.

Timely Delivery

Time is money, and the ability to meet deadlines is crucial in the competitive marketplace. Established manufacturers understand the importance of delivering prototypes in a timely manner, helping you keep your projects on schedule.

Applications of Rapid Prototyping in Various Industries

The versatility of rapid prototyping makes it applicable across numerous sectors. Let's explore some critical industries utilizing these services:

1. Automotive Industry

Automakers leverage rapid prototyping for creating parts and components, allowing them to conduct rigorous testing and refine their designs before full-scale production.

2. Aerospace

In aerospace, rapid prototypes are essential for testing aerodynamics and structural integrity, which are critical for safety and performance.

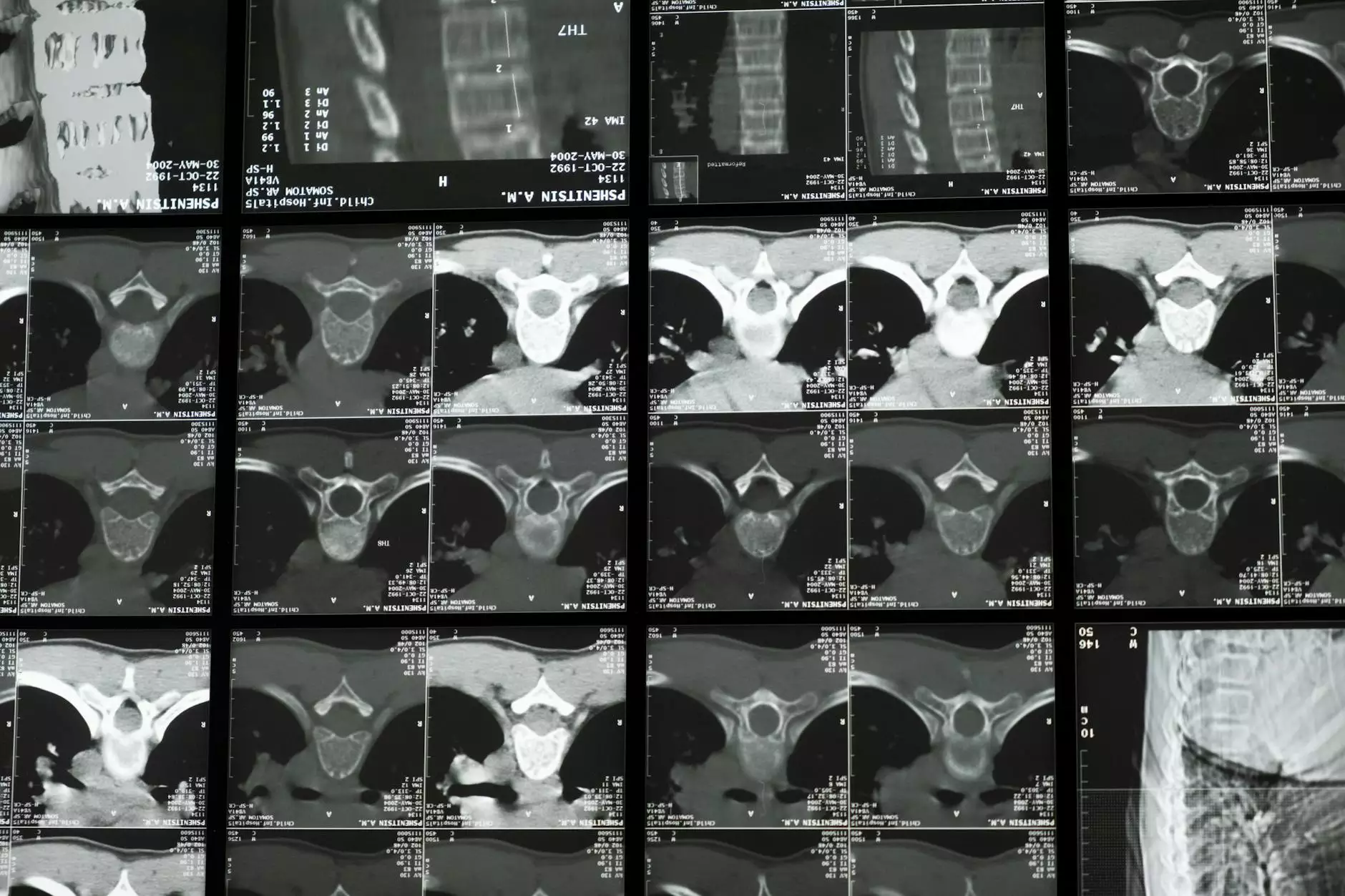

3. Medical Devices

The healthcare sector uses rapid prototyping to develop surgical instruments and implants, where precision and customization are vital for patient outcomes.

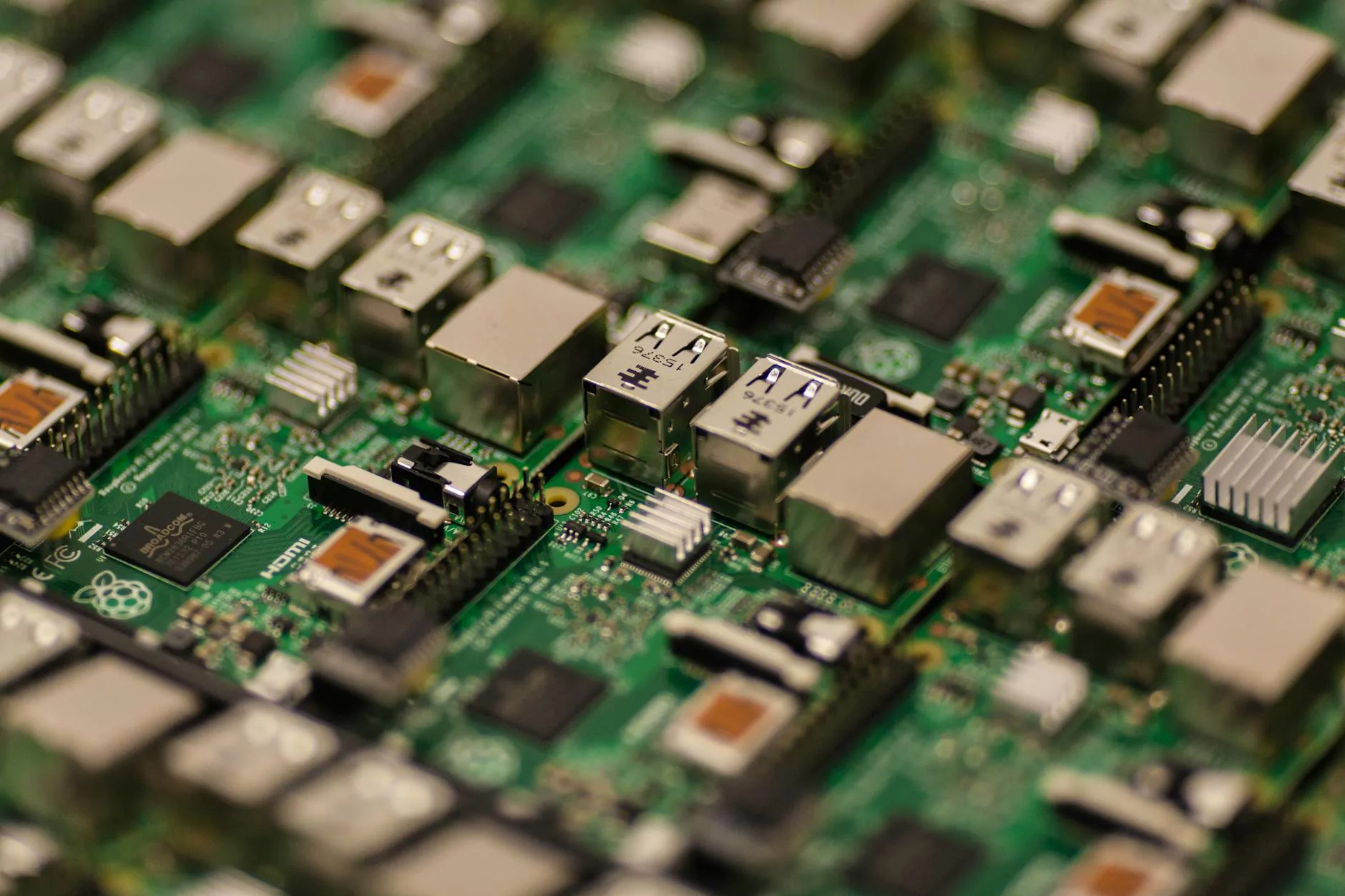

4. Consumer Electronics

With the rapid pace of technology, consumer electronics manufacturers use prototyping to design and test new gadgets and devices efficiently.

5. Architecture and Construction

Architects and builders benefit from 3D models that help in visualizing projects and making essential design decisions before they commence construction.

Future Trends in Rapid Prototyping

As the landscape of manufacturing evolves, so does rapid prototyping. Here are some upcoming trends to watch:

Advancements in Materials

New materials, including advanced composites and bio-compatible substances, are being developed for use in rapid prototyping applications, expanding the possibilities for design and functionality.

Integration of AI and Machine Learning

Artificial Intelligence is set to play a significant role in improving design processes, optimizing the use of materials, and predicting the performance of prototypes.

Increased Sustainability

With growing concerns about the environment, sustainable practices are becoming integral to manufacturing. Rapid prototyping techniques are evolving to minimize waste and enhance energy efficiency.

Conclusion

In conclusion, partnering with a skilled rapid prototype manufacturer can provide your business with a substantial competitive edge. By improving speed, reducing costs, and enhancing product quality, rapid prototyping is revolutionizing the way products are designed and manufactured. As you consider your next project, remember the vital role that rapid prototyping can play in achieving your business goals, and look to expert entities like Deep Mould for transformative solutions.

For additional information on how our expertise in rapid prototyping and metal fabrication can benefit your organization, please visit us at Deep Mould.