Understanding China Plastic Injection Mold and Its Impact on Metal Fabrication

The world of plastic injection molding is not only vast but also increasingly vital in modern manufacturing, particularly when it comes to businesses like DeepMould.net that focus on metal fabrication. This article delves deep into the intricacies of China plastic injection mold, how it enhances production efficiencies, its applications, and why it is a game-changer for businesses aiming for high-quality outputs.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used for producing parts by injecting molten material into a mold. This method is particularly popular due to its ability to create complex shapes with high precision and repeatability. The process involves several key steps:

- Clamping: The two halves of the mold are securely closed.

- Injection: Molten plastic is injected into the mold under high pressure.

- Cooling: The material cools and solidifies into the desired shape.

- Demolding: The mold is opened, and the finished part is ejected.

The Role of China in Plastic Injection Molding

China has emerged as a powerhouse in the plastic injection mold industry, offering numerous advantages that appeal to businesses worldwide. Here’s why:

Cost-Effective Production

Manufacturing costs in China are typically lower than in many Western countries. This is due to factors such as:

- Affordable labor costs

- Access to a wide range of raw materials at lower prices

- Established supply chains that minimize logistical expenses

High-Quality Standards

Despite lower costs, China’s plastic injection molding services adhere to high-quality standards. Many manufacturers invest heavily in modern machinery and technology to ensure precision and durability in their molds. This dual focus on cost-effectiveness and quality makes China a preferred source for many international businesses.

Applications of China Plastic Injection Molds

The applications of China plastic injection molds are vast and varied, serving numerous industries:

1. Automotive Industry

In the automotive sector, plastic injection molded parts are widely used due to their lightweight and durable nature. Components such as dashboards, trims, and interior parts are often created using this process, allowing for both aesthetic appeal and functionality.

2. Household Appliances

From durable plastic casings to intricate internal components, household appliances leverage plastic injection molding to enhance product effectiveness and customer appeal.

3. Electronics

In the electronics field, plastic injection molds are used to create housings and protective parts. The precision achieved through this technique ensures that electronic devices are both aesthetically pleasing and functionally safe.

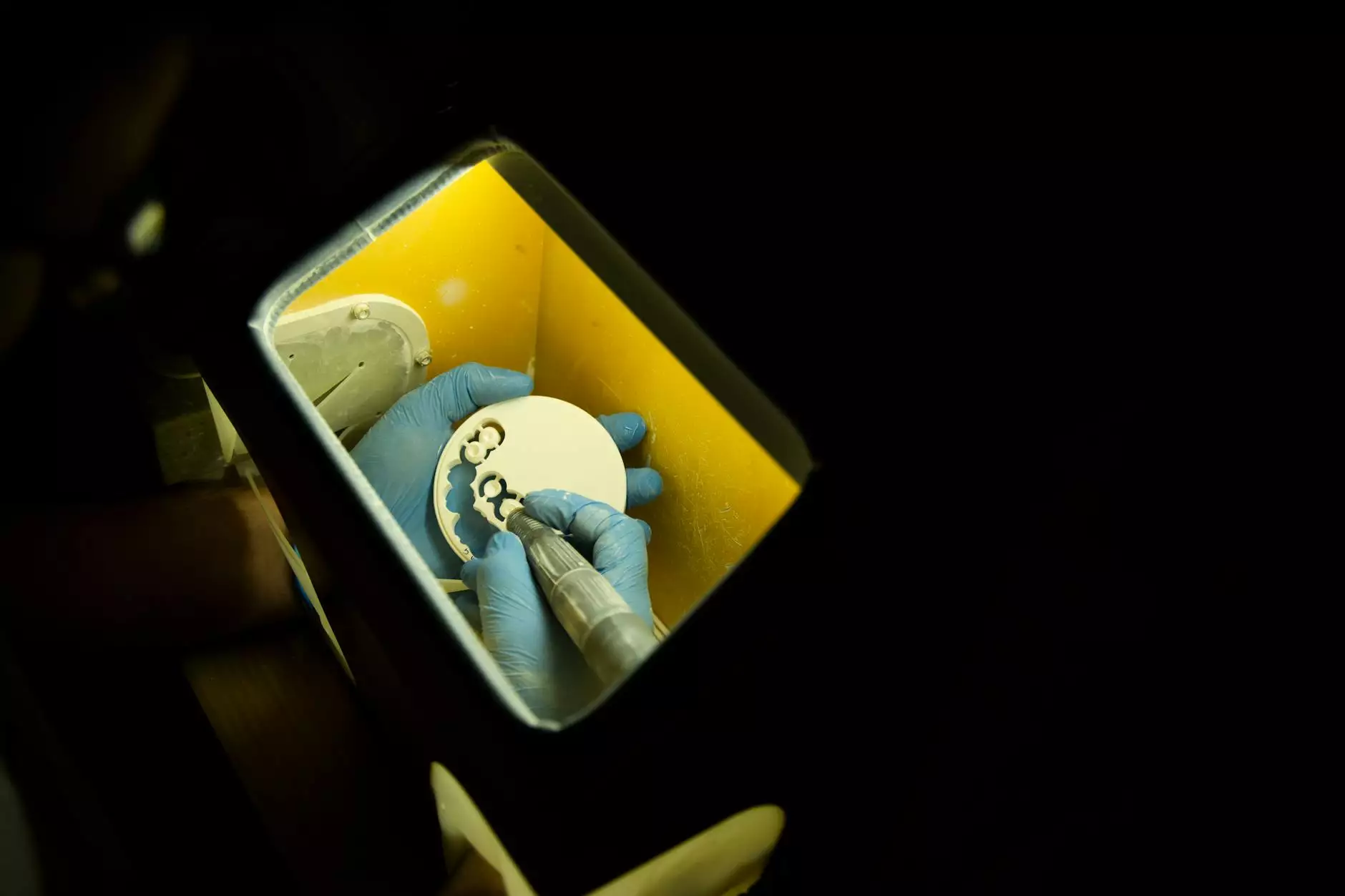

4. Medical Devices

The medical industry benefits greatly from plastic injection molding technology, producing components such as syringes, surgical instruments, and diagnostic equipment that require high levels of cleanliness and precision.

Advantages of Using China Plastic Injection Molds

Businesses that leverage China plastic injection molds reap multiple benefits, including:

1. Enhanced Design Flexibility

The ability to design complex geometries without incurring substantial costs allows businesses to innovate and refine their product offerings. This flexibility is crucial in maintaining a competitive edge in rapidly changing markets.

2. Improved Production Speed

With automated systems and efficient processes, plastic injection molding significantly reduces the time taken to produce parts compared to traditional manufacturing methods.

3. Consistency and Reliability

The precision of plastic injection molding ensures that each part produced is nearly identical, which is critical for industries that depend on standardization. This reliability minimizes the risk of defects and boosts overall quality assurance.

Choosing the Right Manufacturer

When selecting a manufacturer for china plastic injection mold, consider the following factors:

1. Expertise and Experience

Look for manufacturers with a proven track record in the industry. Their experience will reflect in the quality of the molds produced and the efficiency of their processes.

2. Technology and Capability

Evaluate the technology used by the manufacturer. Advanced machinery and technology can significantly improve the quality and precision of the molds.

3. Customer Support

Responsive and knowledgeable customer support can make a huge difference, especially when dealing with complex projects or tight timelines.

Conclusion

The plastic injection molding industry in China presents an unparalleled opportunity for businesses looking to enhance their manufacturing processes. By understanding the intricacies of china plastic injection mold and its applications across various sectors, companies can optimize their operations for greater efficiency and product quality. Investing in this technology not only supports metal fabrication endeavors but also enhances overall business growth. For anyone looking to explore further, DeepMould.net is your go-to resource for cutting-edge insights and quality manufacturing solutions.

Future Trends in Plastic Injection Molding

As technology continues to evolve, the future of plastic injection molding is set to be transformative. Here are some trends to watch for:

1. Biodegradable Plastics

The push for environmental sustainability is driving the development of biodegradable plastics that can be used in injection molding processes. This could significantly reduce plastic waste and impact on the environment.

2. Smart Manufacturing

The integration of IoT and smart technologies in manufacturing processes is set to enhance efficiency. Predictive maintenance and real-time monitoring will become standard practices, improving production outcomes.

3. Advanced Materials

New materials, including composites and hybrids, are being developed for injection molding, providing stronger, lighter, and more versatile components that can cater to specific application needs.

In Summary

Understanding the dynamics of china plastic injection mold is crucial for businesses striving to maintain relevance in an ever-evolving marketplace. By leveraging quality manufacturing, innovative designs, and efficient processes, companies can set themselves apart from the competition and thrive in their respective industries. The potential for growth is immense, making now the perfect time to explore the benefits and applications of this invaluable technology.